100% Danish-made injection molded plastic parts

- Advanced quality components developed by skilled engineers

With more than 50 years of experience in plastics manufacturing, we know exactly what it takes to make your product even better.

These are the industries we help right now

Our quality plastic parts are used in a wide range of industries - and we can definitely help your company optimize your products too.

Plastic infrastructure components need to be of high quality as they are exposed to high wear and tear and many influences: high heat, cold, pressure, wind and weather. We have the experience and expertise to find the right long-lasting materials for infrastructure.

Contact us and find out more.

We have been supplying quality components to the defense industry for many years. Naturally, the plastic parts are designed to perfectly fit the needs of the defense industry.

Contact us and find out what we can do for your business.

In the medical industry, the focus is on quality and documentation of plastic parts. This places great demands on the raw materials used in the plastic components. At Molytex, we have the expertise to handle materials and raw materials that meet the industry's high standards.

Want to know more about how we can help your business? Contact us here

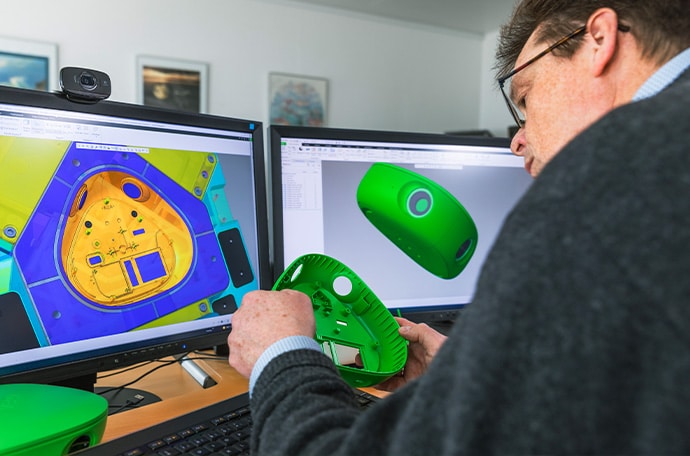

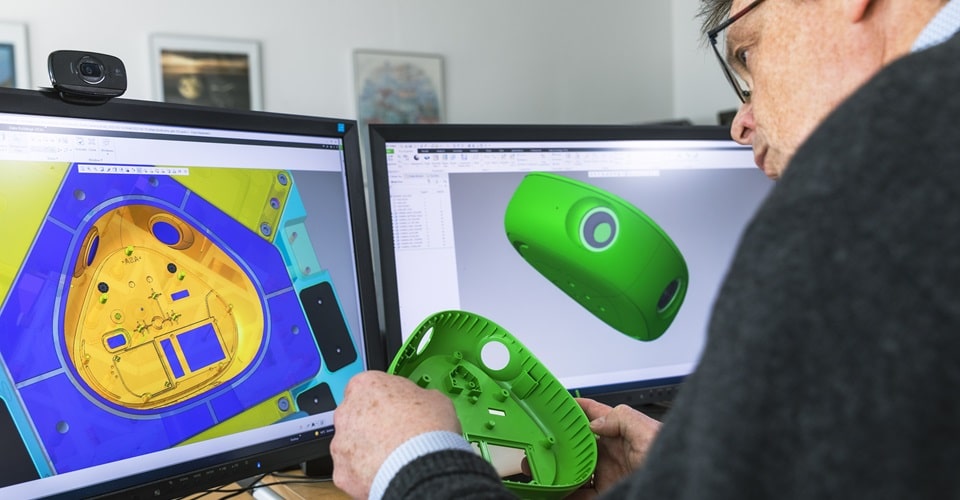

We are involved in the development phase, where form and function come together, also in terms of material selection. We have a very wide range of raw materials with different properties, and of course we help you find the perfect material.

Learn more about how we can make your product even better. Contact us

Do you have an idea for a new product? Our engineers will help you mature your product and convert 3D printing into something that can be injection molded. It's all about material selection and tool design, and we are experts in this field.

Want us to help you get your product to the finish line? Contact us for an informal chat

Want to know more about who we are and what we can do for you? Find out more here

Recycled plastic - an investment in the future

Do you want to create a greener profile for your business? Of course, we use recycled plastic wherever possible, and there are several advantages to choosing this option.

Firstly, recycled plastics have a smaller environmental impact, saving the environment from the CO2-emissions associated with the extraction of raw materials. Secondly, it allows you to stay ahead of future environmental regulations. Read more about the benefits of recycled plastics.

Plastic can be a sustainable choice

Many people think of plastic as a climate-damaging material, but in many cases our plastic parts can actually make your product more sustainable. This is because plastic parts can often replace metal components that have a large carbon footprint in the production process.

When you choose Molytex, you get a Danish plastic manufacturer that meets all environmental requirements. At the same time, you get quality plastics made from traceable materials with material certificates.

Green production

We consider the environment at every stage of production. For example, we work closely with you to find the right material and design for your product to avoid waste and production errors.

We place high demands on our suppliers for environmentally friendly materials, processes and transportation, and we continuously evaluate our own production processes and optimize where we can. All to ensure that the production of your plastic parts is as green as possible. Want to know more about what we do to make our production greener?

Capacities

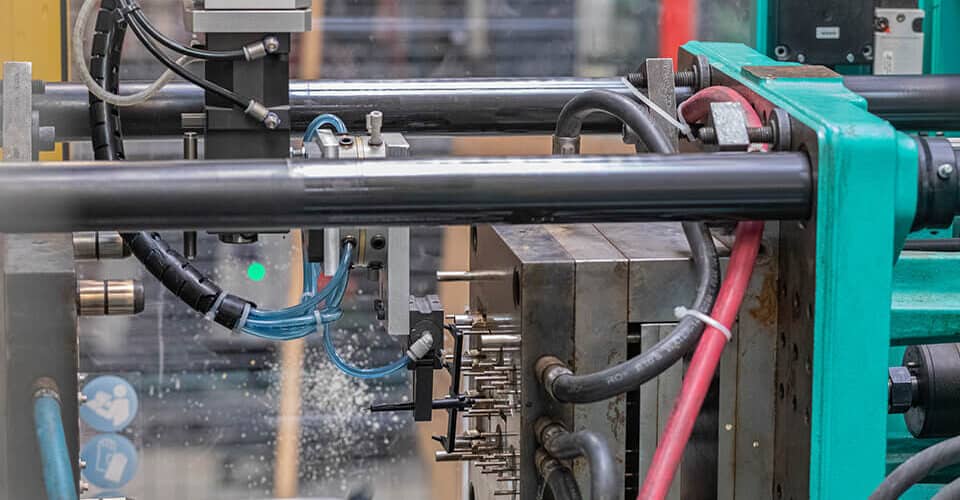

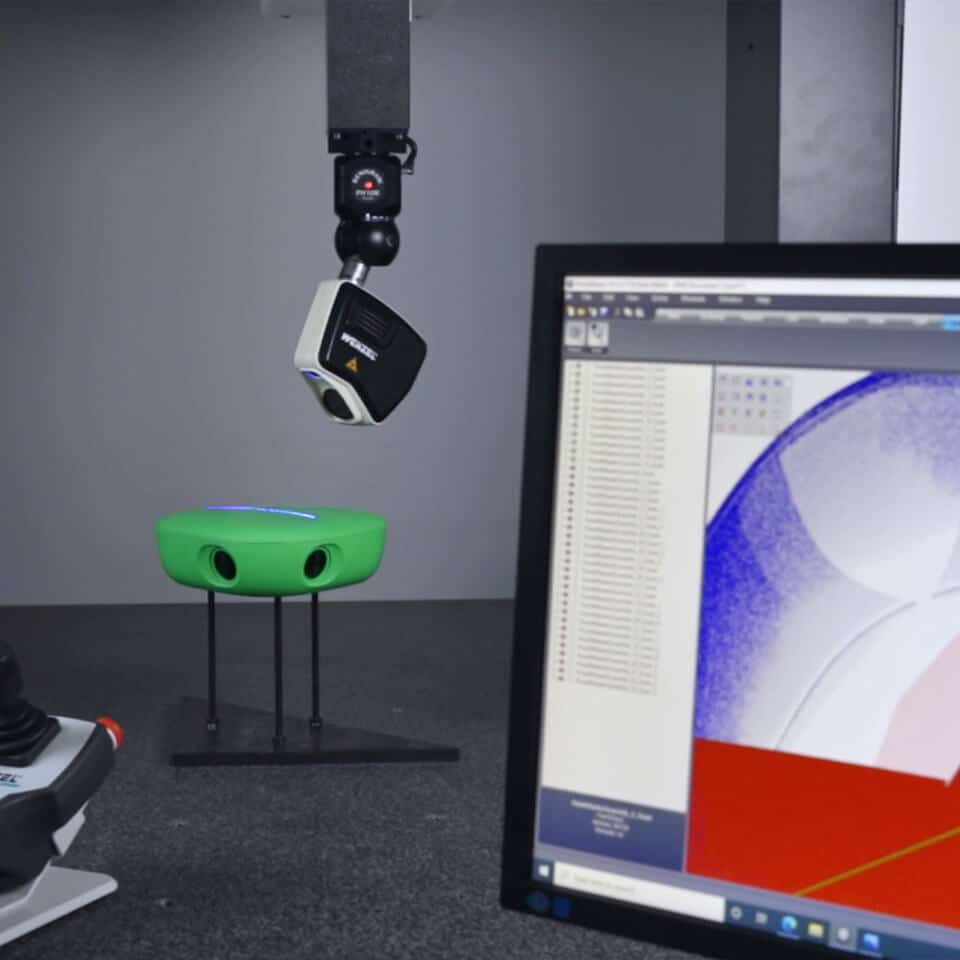

INJECTION MOLDING IN PLASTIC

Injection molding is an efficient and affordable way to produce plastic parts of all shapes and sizes.

Know-how

PRODUCT DESIGN AND DEVELOPMENT

Our engineers help you develop and optimize your product with high-tech plastic parts with material certificates.

About us

Molytex has been producing quality components in Danish plastic since 1965. Today, the factory's 35 injection molding machines run around the clock to deliver plastic parts of the highest quality.

Our experts advise and develop products for a wide range of industries and companies.

Companies we have helped

We've optimized products for countless companies over the years - and we're ready to make your product even better.

Short production time and low cost

Injection molding is an efficient production process that offers great design flexibility, short production time and low production costs. At the same time, the molds ensure that you get a consistent result - every time.

When you choose us, you get high delivery reliability, competitive prices and less waste.

Get high-tech plastic blanks

At Molytex, you get injection molded plastic parts in Danish quality plastic. There are several advantages to this. Firstly, you get long-lasting plastic parts that deliver what they promise. Secondly, plastic is a highly flexible material that can be designed to have exactly the right properties and shape for your product.

Let us optimize your product

Do you need to optimize your product with high-tech, high-quality plastic parts?

Our engineers will help you find the best solution so you get plastic parts with the right properties and certifications for your product. Of course, we also help you figure out how the plastic parts should be designed to optimize your product as much as possible.