Green production of high-tech plastic parts

- How we make plastic production as green as possible

Do you want plastic parts with minimal environmental impact and high quality?

With Molytex, you get a partner that is dedicated to the green agenda. This means that we have made our production as green as possible - in all phases:

- Product development

- Plastic production

- Injection molding

Learn more about how we incorporate sustainability into our everyday life here

A greener product development

We consider the environment in several ways when developing plastic parts for your product. For example, it's important that the plastic blank is made of a material that suits your product - both its other components and its application.

As part of product development, we naturally also consider how we can optimize the production process so that it requires as little energy as possible.

Want to know more about our product development?

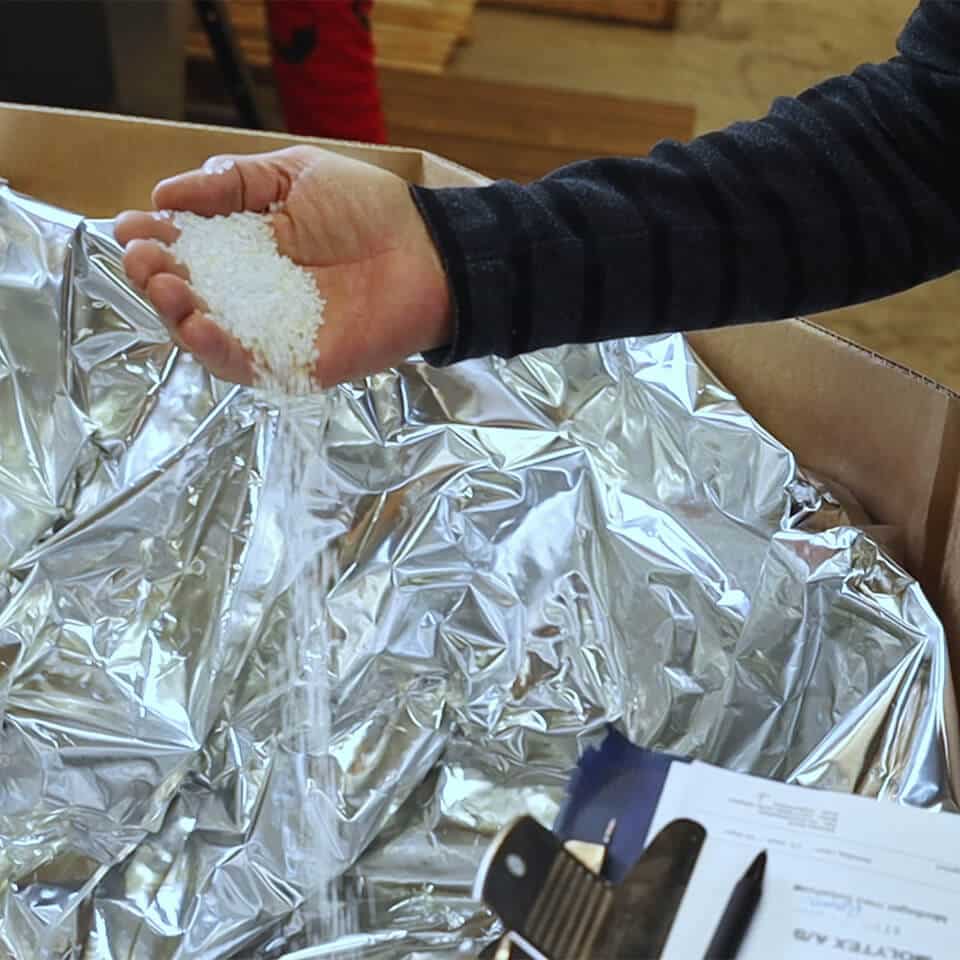

Green plastic production

We are continuously working to make our plastic production more green. Among other things, we do this by:

- Require our suppliers to use environmentally friendly materials, processes and transportation modes

- Stay ahead of all environmental requirements

- Understand your needs and choose the right materials to avoid waste and production errors

Read more about our plastic production here

Injection molding

- a climate-friendly form of production

At Molytex, we are experts in injection molding of plastic parts. The injection molding process has several advantages, including high precision and price efficiency.

We continuously evaluate our production processes to see where we can save energy and materials. In addition, we plan our operations to optimize energy as much as possible.

When planned correctly, injection molding is the most climate-friendly production method when it comes to plastic parts because:

- There is significantly less waste with injection molding than with other production methods.

- Injection molded plastic is recyclable because it rarely contains binders that contaminate the plastic.

- Injection molding is - with the right molding - an energy-efficient way to make plastic parts because the plastic parts only need to be handled once.

Read more about the benefits of injection molding here