Insourcing

- Get all the benefits of Danish plastic production

Is your company experiencing long lead times on plastic parts produced abroad? Is your supply chain affected by changing external circumstances? Do you want to ensure your product meets Danish standards?

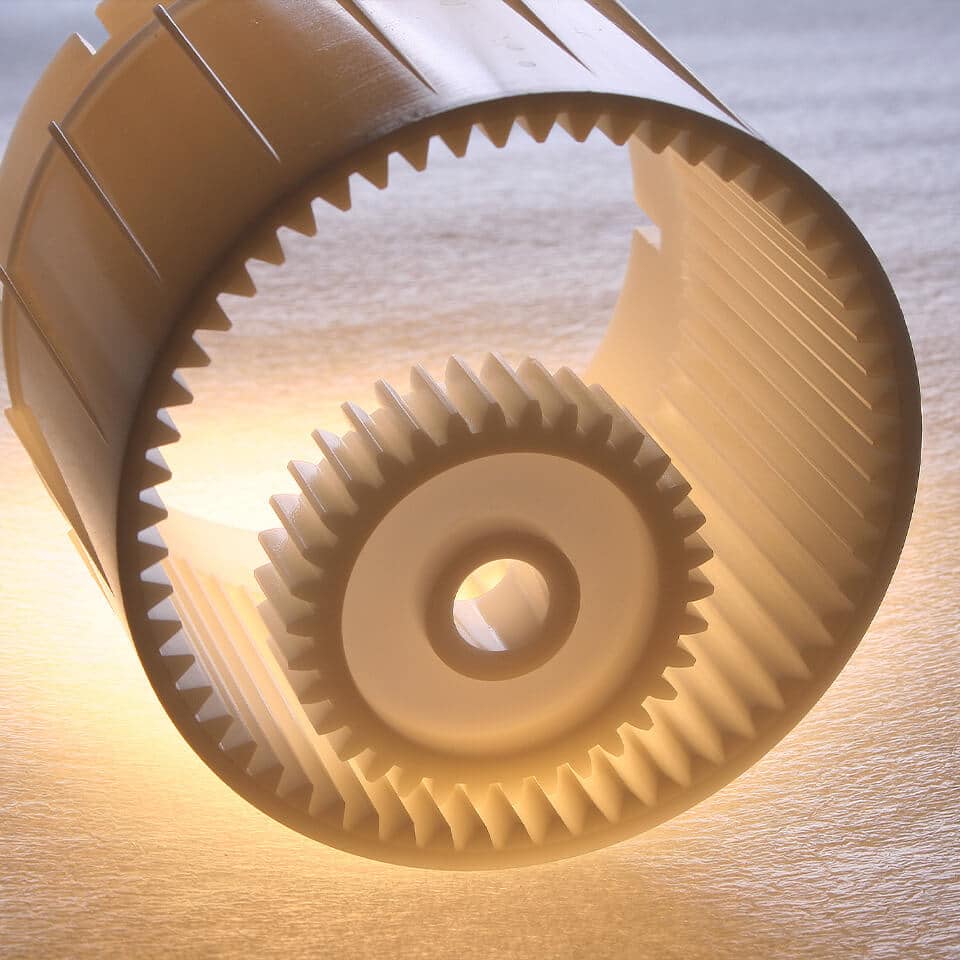

Insourcing is your opportunity to gain control over the production of your plastic parts. At Molytex, we injection mold high-tech plastic parts at our factory in Glostrup. We use leading European raw material manufacturers, so you can be sure that your product meets the high quality standards we have in Denmark.

The financial benefits of insourcing

Insourcing saves your business more costs because:

- You save on transportation costs. When you have your plastic parts produced in Denmark, you save expensive transportation costs from abroad. You also avoid delays that can ultimately result in costly production stoppages.

- You can quickly adjust the capacity. The lines of communication are shorter when you use a Danish plastic manufacturer. This means you can quickly adjust capacities to your needs and the demand for your product. That way, you avoid overproduction and waste or not being able to keep up with the demand for your product.

- You get greater delivery reliability. When you insource your plastic production, you get greater security of supply of plastic parts, so your company can always follow the demand for your products.

Here are the benefits of our plastic blanks

Why consider replacing components in your products with plastic? There are several good reasons:

- Plastic is cheaper to manufacture than many other materials.

- Plastic is a more environmentally friendly alternative to metal*.

- You get greater delivery reliability as all plastic parts are produced in Denmark.

- You get a certified plastic product made from traceable materials.

- Our experts are always available for sparring and product advice.

Read more about the sustainability of our products here

More control over quality

It used to be popular to outsource the production of, for example, plastic parts to other countries, but now most people have realized the benefits of insourcing production. In a market where sustainability, certifications and quality control are becoming increasingly important, it is an advantage to be able to document the entire production process.

Learn more about the injection molding production process here

When you choose Molytex as your partner, you get full control and transparency in all aspects of the production process - from material selection to finished product. This way you can be sure that your product meets all requirements and has the necessary certifications.